Błąd formatu e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Aktualności

Prawidłowe użycie rękodzieło

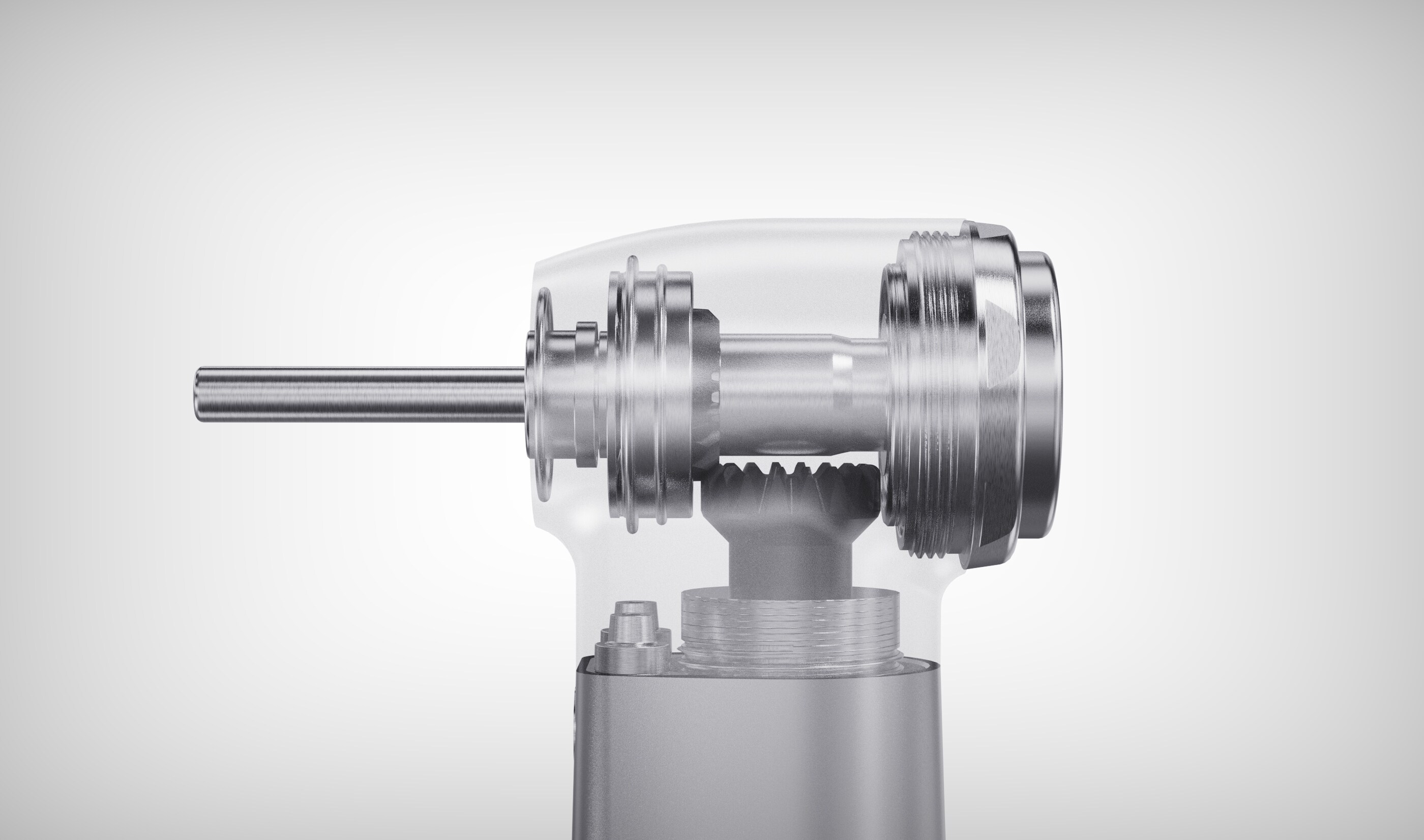

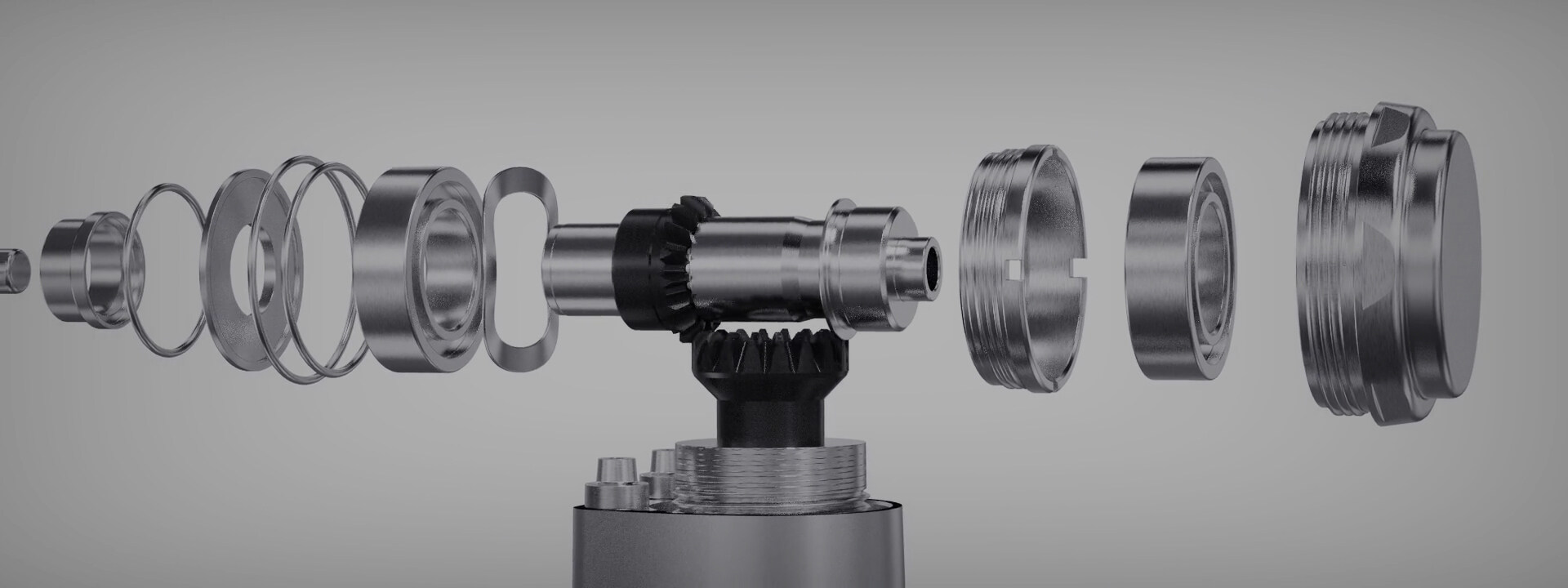

Zasada pracy dentystyszybki rękajest napędzany sprężonym powietrzem w celu obracania koła wiatru z dużą prędkością, w ten sposób igły dentystyczne do ukończenia wiercenia i szlifowania zębów. Zgodnie z międzynarodowym standardem produktu (ISO7785-1) ręka z prędkością obrotową ≥ 160000 obr./min można nazwać dentystyczną ręką podręcznika.

Handpice jest bardzo precyzyjnym instrumentem medycznym dentystycznym. To, czy można go użyć i utrzymywać prawidłowo, wpłynie bezpośrednio na żywotność obsługi ręki. Wymaga to od użytkowników rękodzieła opanowania prawidłowego użycia i konserwacji rękodzieło.

Prawidłowe użycierękaS

Właściwe podejście

Ponieważ łożysko ręczne jest bardzo małe, nie może znieść zbyt dużej siły, więc metoda walcząca powinna być stosowana w miarę możliwości, a wiertło uderzenia nie należy stosować w pośpiechu. Nieprawidłowe metody mogą spowodować uszkodzenie łożyska w bardzo krótkim czasie, szczególnie podczas przygotowywania pieczonych zębów magnetycznych.

Wybierz obowiązujące igła

Igły używane do ręcznych elementów z różnymi funkcjami, funkcjami i prędkościami obrotowymi mają określone wymagania. Należy użyć igieł, które spełniają obrotową prędkość rękodzieła. Nie używaj wygiętego, wstrząsającego, noszenia, zbyt długich lub zbyt krótkich igieł, zwłaszcza mini ręcznie. Całkowita długość igieł (w tym uchwyty) nie może przekraczać 17 mm. Średnica igły powinna wynosić od 1,592 do 1,6 mm przy użyciu słuchawki igły dławika. Jeśli średnica igły jest mniejsza niż 1,59 mm, wyleci się z powodu niepewnego zacisku, co spowoduje wypadki medyczne.

Prawidłowy smarowanie

Przede wszystkim należy wybrać kwalifikowany olej smarowy. Obecnie niektóre niedrogie „smary do czyszczenia ręcznego” na rynku wykonane są z niskiej jakości olejów przemysłowych, które wyrządzają wielkie uszkodzenia łożysk ręcznych. Po drugie, podczas normalnego użytkowania dodaj olej smarowy oczyszczający co najmniej dwa razy dziennie, i wyczyść i smaruj rękę przed i po sterylizacji.

Odpowiednie spożycie ciśnienie

Jeśli ciśnienie wlotowe powietrza jest zbyt niskie, prędkość i moment obrotowy słuchawki będą zbyt niskie, co wpłynie na normalną operację. Jeśli ciśnienie jest zbyt wysokie, łożysko zostanie szybko uszkodzone. Prawidłowe ciśnienie wlotu powietrza wynosi 0,20 - 0,25 MPa. Prawidłowe ciśnienie wlotu powietrza odnosi się do ciśnienia zmierzonego w złączu wlotowym powietrza z tyłu ręcznego elementu, a nie do ciśnienia manometru na stole obróbki. Istnieje niewielka różnica między nimi. Z powodu utraty rurociągu ciśnienie wskaźnika manometru na stole obróbki jest większe niż ciśnienie wlotowe ręcznego elementu.